Variant configuration

Variant configuration is a key aspect of modern manufacturing that enables companies to respond to individual customer requirements and offer customized products. At BDF EXPERTS, we use our extensive expertise and innovative methods to make variant configuration efficient and effective.

Intelligent variant management

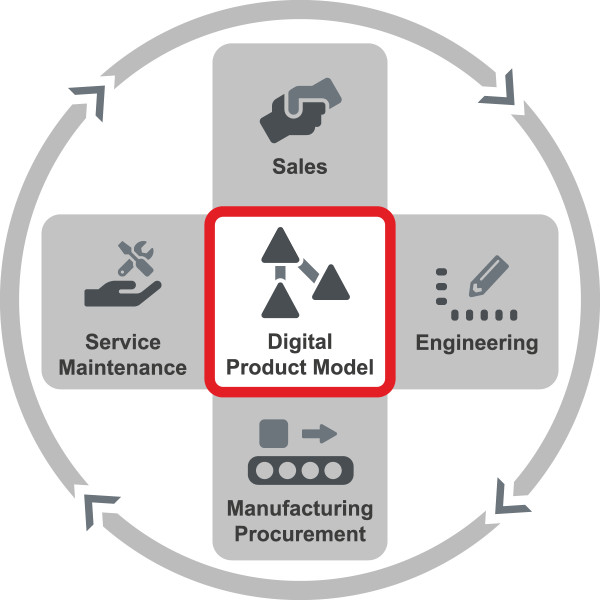

Variant configuration plays a key role for complex products in mechanical and plant engineering across the entire supply chain. Intelligent variant management can optimize your order handling processes by reducing the internal complexity of product variants while increasing flexibility to respond to individual customer requests. It also offers the opportunity to optimize production processes, plan procurement and warehousing better and save resources.

Our approach at BDF EXPERTS

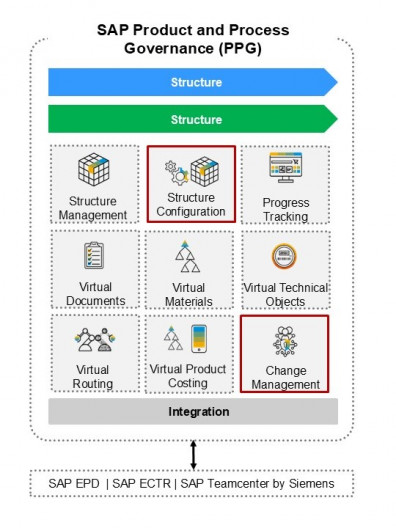

At BDF EXPERTS, we use SAP Product and Process Governance (SAP PPG) to generate multi-variant products with complex bills of materials and routings.

- With SAP PPG, we offer a powerful solution that makes it possible to manage complex product structures and control processes throughout the entire product life cycle.

- Data from CAD systems, e.g. from SAP ECTR, documents and deadlines are included.

- Our concurrent calculation enables you to calculate the exact costs of every possible variant during order processing.

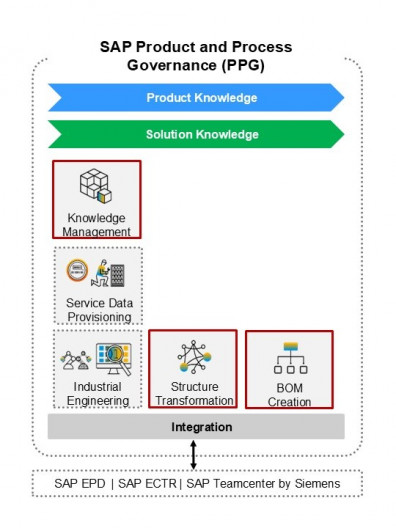

Knowledge management

Incorporate product and configuration knowledge directly into your product structures.

- With the help of knowledge management, configuration knowledge can be preconfigured and generated directly for each class and object.

- By using the knowledge centres in the PPG, this knowledge can be used directly in SAP variant configuration.

- By using characteristic spaces and knowledge types, you always have an overview of the classes and objects used in the variant configuration and avoid redundancies.

Change management

Utilise the comprehensive change management functions in PPG.

- Simple and complex multi-layer status networks in PPG.

- Integrated baseline management for change visualisation.

- Change all data generated with PPG with change number.

- Validity control based on the SAP change number.

Bill of materials

Derive your required parts lists directly from the PPG data.

- Material BOMs can be generated in the desired applications, sales order BOMs, project BOMs, equipment BOMs and functional location BOMs.

- This supports the global engineering and global production approach, in which production plants can be integrated in a global network via intercompany processes with the appropriate BOM type.

- The Factory Control Centre (FCC) also allows you to automatically transform engineering BOMs (EBOM) into manufacturing BOMs (MBOM) in order to seamlessly integrate logistical follow-up processes.

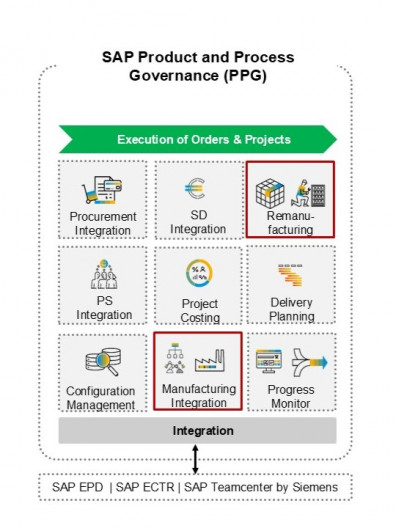

Production/reprocessing integration

Generate planned orders, production orders, ERP routings and production BOMs directly from the PPG. In addition, production data packages can be configured using the SAP variant configuration. These can contain various production parameters and work instructions and can be transferred directly to the MES.

- In addition to production processes, reconditioning processes can also be mapped and recorded as maintenance files.

- Using the SAP variant configuration, the actual reprocessing scopes can be determined after the findings and transferred to the MES with the corresponding work plan and components.

- Integration in service and maintenance means that equipment master records can be created, assigned or updated directly after reconditioning.

Structure configuration

Use templates, module libraries or guided structure copies for the simple and standardised creation of order-neutral or order-related structures with rule-based number assignment. For example

- Product and document structures can be created, classified and inherit characteristic values.

- The structures can be created without master data and contain various views such as costs, deadlines, engineering, production, project allocation, service data, dispatch planning, etc.

- The master data can be generated directly from the structure in the further course of order processing.