Service and Asset Management

The maintenance and servicing of machines and systems are crucial for productivity, quality and safety. Reduce downtime and the cost of spare parts and repairs through regular and preventive maintenance and effective service and maintenance management.

Efficient Service and Asset Management

A well-developed concept for service and maintenance forms the basis for efficient operation and maintaining the service life and performance of your systems. Clear management of service and maintenance data is essential in order to identify potential problems at an early stage, minimize unplanned downtimes and therefore costs, and ensure the safety of personnel.

Our approach at BDF EXPERTS

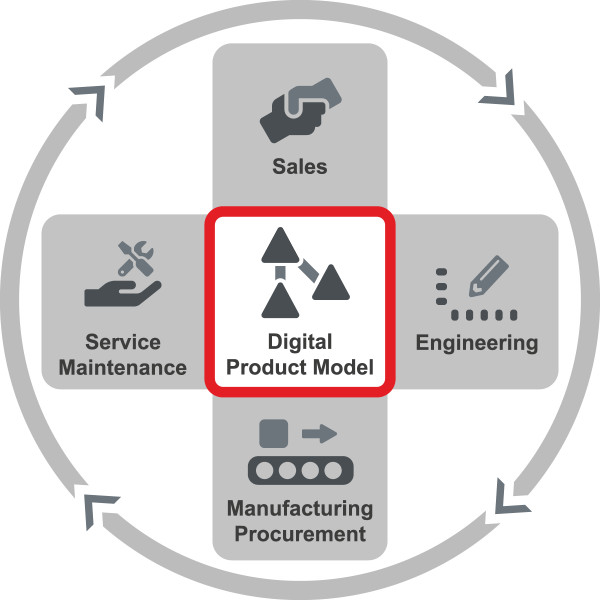

BDF EXPERTS is a leading provider of maintenance and service solutions for mechanical and plant engineering. With the help of SAP Product and Process Governance (SAP PPG), we offer you holistic and integrated support for your processes:

- (Semi-)automated setup of the system structures

- Automated provision of spare parts structures (spare parts lists) from PPG

- Seamless integration of the derived structures into standard SAP service and maintenance processes

- Usability of the PPG structures and the derived maintenance and service structures in the SAP standard system configuration for mapping the target configuration and the configuration check in the event of configuration changes

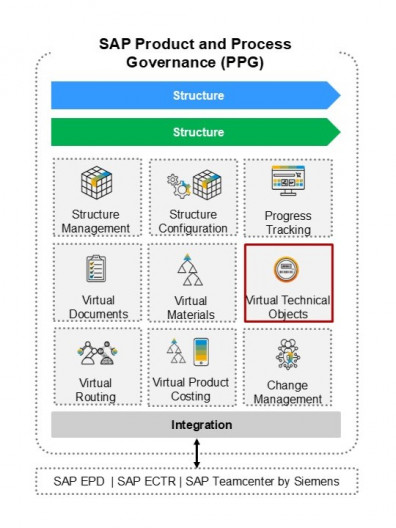

Virtual technical objects

Use virtual functional locations and equipment when setting up service and maintenance structures in SAP PPG. The functional locations, equipment and the links to each other can be generated directly from these for subsequent service tasks. Create further structures for documentation in addition to the planning structure. In this way, documents can be structured without redundancy using folder systems, which in turn can be linked to each other. The third essential component for setting up a digital twin for plant operation is spare parts structures, which can be used in subsequent service processes.

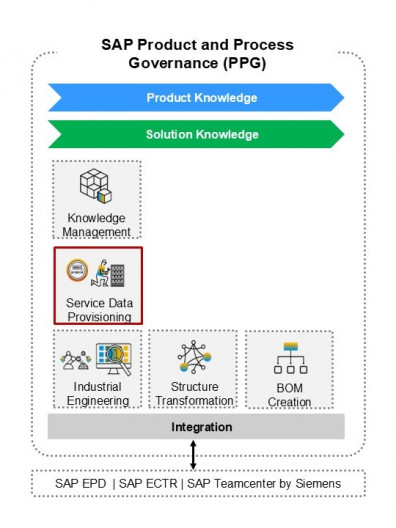

Provision of service data

Build your digital twin from the PPG planning data for the subsequent operation of the plant by generating the functional location structure and the corresponding equipment for an entire plant complex based on the engineering structure and the functional elements it contains. The spare parts for a piece of equipment can be mapped via equipment BOMs or material BOMs with maintenance usage and generated directly from SAP PPG. You can display the contents of the customer documentation in a separate structure and link it to the functional locations and pieces of equipment.

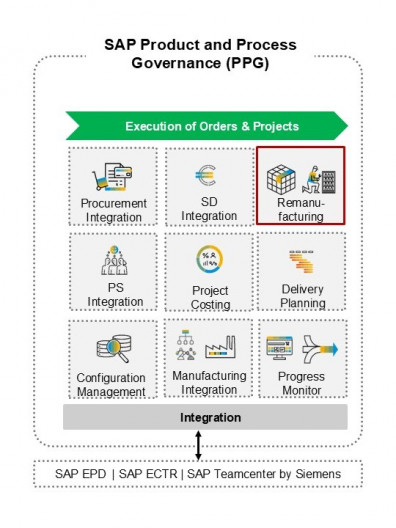

Reprocessing integration

With SAP PPG, you are able to map your reconditioning processes and record them as maintenance files. Using the SAP variant configuration, the actual reconditioning scopes can be determined after the findings and transferred to the MES with the corresponding work plan and components. Integration in service and maintenance means that equipment master records can be created, assigned or updated directly after reconditioning.