Supply Chain Management

Supply chain management includes all activities, information and resources that accompany a product from its creation to delivery to the customer. For example, the supply chain can be divided into procurement, production, packaging and shipping through to delivery, storage and sale to the end customer.

Effective supply chain management: the key to on-time delivery and quality assurance

Use your supply chain management to ensure that your products reach the customer on time and in the right quality. With the increasing complexity of supply chains, targeted SCM is becoming more and more important. By optimizing processes along the supply chain, SCM aims to minimize costs and maximize productivity, product quality and thus customer satisfaction and sustainability. In order to optimize business processes, efficient IT tools are an important instrument for achieving these sometimes competing goals.

Our approach at BDF EXPERTS

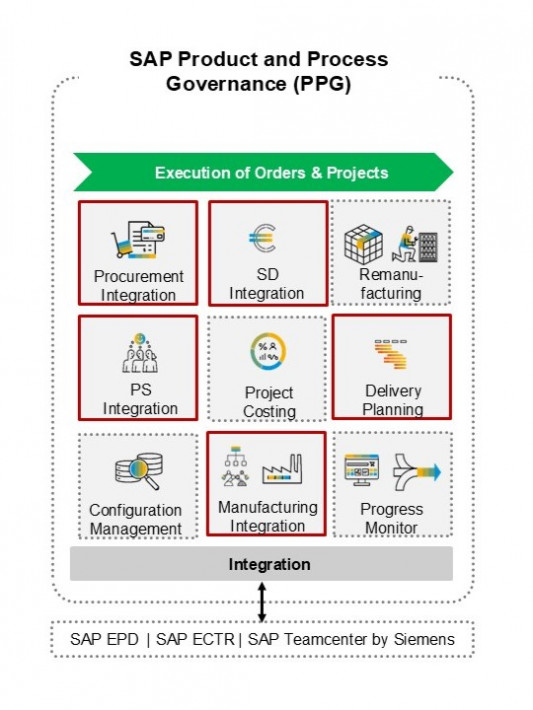

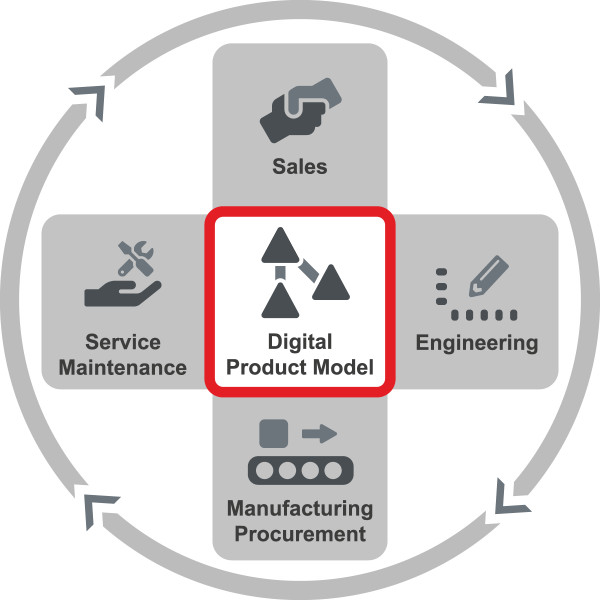

In SAP Product and Process Governance (SAP PPG), you can map all processes along the entire supply chain. All order trigger types are supported - whether MTS, MTO, CTO, CTO+ or ETO. The SD and project system integration in particular provides you with a solution in which you can manage the entire sales order processing in one system.

SD integration

Carry out your sales configuration ("high-level") in SD and automatically generate the corresponding technical order structure (TOS) to control all subsequent processes and complete SD order processing.

PS integration

With PS integration, you can first define the global scope of delivery and services in the technical order structure (TOS) and then process it across several projects in the respective delivery organizations. TOS items can be integrated automatically into the WBS and network structures based on rules.

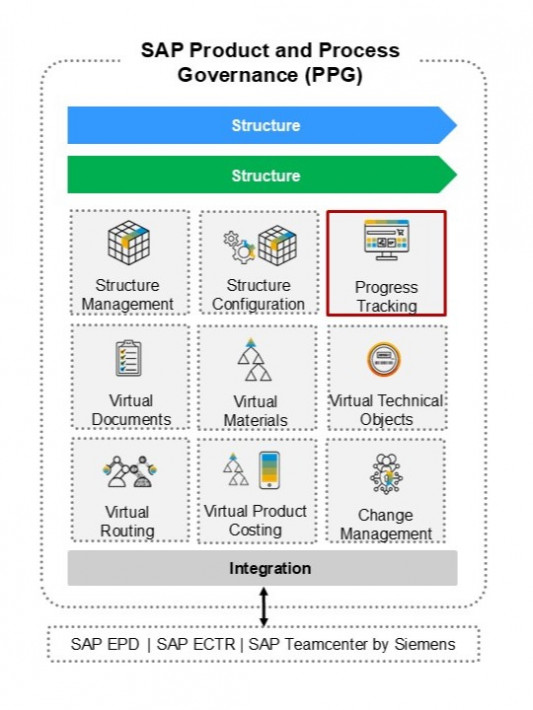

Project Tracking/Monitor

Progress tracking can be used for any level of detail at the lowest level in each project phase so that you can always keep an eye on deadlines in complex projects or product structures. For example, the creation of documents and material masters can be planned and tracked. Dates can also be inherited in the PPG structure and calculated according to the selected scheduling profiles. In the Progress Tracking Cockpit, entire projects or parts thereof can be selected for processing, which makes processing easier. More complex reporting requirements can also be mapped with additional available data.

Procurement integration

The overall "Digital Purchasing" process offers you an end-to-end process chain from product development and prototype construction through to series production. A link is created here between PPG product structures, material masters, general purchasing documents, item-specific purchasing documents and outgoing and ordered incoming documents. In the doc collector integrated into the purchasing transaction, the purchaser receives an overview of all outgoing and planned (ordered) incoming documents. Integration into collaboration platforms allows the entire process to be fully automated and digitalized.

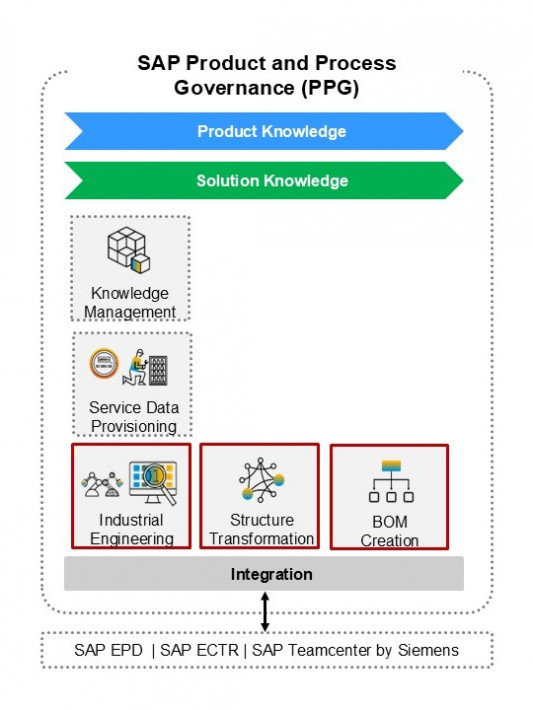

Industrial Engineering

You can handle the simultaneous development of products, their production resources and production processes either in a joint PPG structure or separate PPG structures. Depending on the overall process (MTS, MTO, CTO, CTO+, ETO), work preparation can be carried out independently of the sales order process or only after order configuration or engineering. This results, for example, in logistics parts lists, work plans, work instructions, production parameters or BANFs for the procurement of production resources.

Bill of materials creation

Derive your required parts lists directly from the PPG data. Material BOMs can be generated in the desired uses, sales order BOMs, project BOMs, equipment BOMs and functional location BOMs. This supports the global engineering and global production approach, in which production plants can be integrated in a global network via intercompany processes with the appropriate BOM type.

Structural transformation

Carry out structure transformations manually or automatically from the CAD structure to the production structure and reproduce them in full. For example, you can map the aspects of different production processes in different plants, different logistical aspects of the assemblies or introduce material items that are not taken into account in engineering.

Production integration

Generate planned orders, production orders, ERP routings and production BOMs directly from the PPG. In addition, production data packages can be configured using the SAP variant configuration. These can contain various production parameters and work instructions and can be transferred directly to the MES.

Delivery planning

As the planning structures for production and procurement do not have to match the planning of deliveries, SAP PPG offers you the option of mapping such issues in the delivery planning structure. So-called PPG shipping units can be defined there, which are transferred to logistics processing through the automated generation of SD delivery documents.