01.11.2024

End-to-end Engineer-to-Order Processes

QLAR (formerly: Schenck Process Europe GmbH)

|

Location: |

Darmstadt |

|

Industry: |

Mechanical and plant engineering |

|

Products and Services: |

Weighing and conveying |

|

Number of employees: |

Approx. 2,500 worldwide |

| Website: | https://www.schenckprocess.com |

Click here for the success story in German.

QLAR is a leading global supplier of sustainable products, integrated solutions and services for process-critical bulk solids applications. Headquartered in Darmstadt, Germany, the Group has more than 2,500 employees in over 20 countries on four continents and focuses on food, chemicals and high-performance materials as well as infrastructure and energy market segments.

The product range includes solutions for industrial weighing, dosing, conveying, size reduction and classification, mixing and blending as well as related digital applications. The group was acquired by Blackstone International in 2017 and generated sales of over 750 million euros as at 31 December 2021.

|

Challange: |

No defined requirements for processes |

| Task and objective: |

Establishment of an EtO process in S/4 greenfield with the help of SAP PPG. |

| BDF products and SAP modules used |

SAP PPG, (TOS with Material & Document Structure, Easy Cost Planning) |

| Customer benefit: | Consolidated and optimized processes in a common global SAP S/4 HANA for all locations as a starting point for future expansions. The legacy systems consolidated as a result will be phased out. |

At times, QLAR worked with a fragmented system landscape. Due to the organic growth of the company, as well as mergers and acquisitions, there was a large number of isolated solutions from different software providers. Many of the more than 40 branches used their own tools and workarounds, which were limited to non-process-integrated functions. For example, documents were stored in network drives because there was no integrated document management.

BDF EXPERTS and CIDEON have been working together successfully for a long time and are able to implement an integrated and process-oriented solution in this demanding project. Together, we carried out a proof of concept (PoC) in two parallel sub-projects to check the feasibility of SPG's project requirements with a new IT solution (SP1 "SAP PLM/PDM", SP2 "Global Engineering").

The implementation of the PoC's was carried out on both sides (Cideon and BDF) using best-practice methods. At the end of the two PoC's, it quickly became clear that the SAP Engineering Control Center (SAP ECTR) and SAP Product and Process Governance (SAP PPG), which were previously unknown, were exactly the right solutions. First of all, the existing legacy systems (NON SAP ERP, PDM & file system) were to be replaced by a new S/4 HANA system. As a further project-specific requirement, two of the European sites (Great Britain and the Czech Republic) had to work in the new S/4-HANA system with an identical EtO (Engineer to Order) process. The project was carried out in three project locations: Germany, the UK and the Czech Republic.

Definition of project steps

In a preliminary project, workshops were held in cooperation with SPG and CIDEON to identify possible future product life cycle process steps (PLM). The PLM focus here was on three areas:

- The first focus was on the processing of CAD data by SAP ECTR (taken over by the partner CIDEON) and the data transfer to SAP PPG.

- Furthermore, SAP PPG was to incorporate the received material BOMs into logistical processes.

- The third PLM focus was on the processing of documents through the use of the SAP DMS, as well as SAP PPG for structured storage and use.

Accompanying the workshops, the core process steps in the SAP system were presented to the workshop participants by the BDF model factory. The processes presented in the model factory were gradually adapted in SPG's development system and implemented with the teams.Accompanying the workshops, the core process steps in the SAP system were presented to the workshop participants by the BDF model factory. The processes presented in the model factory were gradually adapted in SPG's development system and implemented with the teams.

From CAD data to project bill of materials

For a sales order with EtO processes, an SAP project is created and the ERP processes are controlled via an SAP project BOM. With the use of the project BOM, global, order-neutral material BOMs can be automatically converted into project BOMs by SAP PPG and thus adapted to specific customer orders. The originally used BOM is not changed. In order to start this process as efficiently as possible from the CAD data, two working principles were defined:

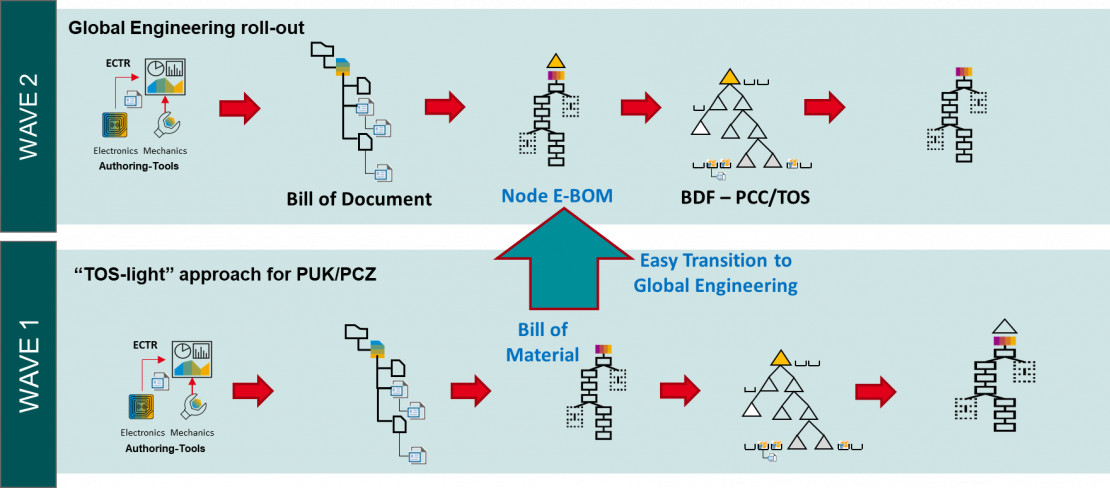

A1 (TOS light): The quotation process first generates the TOS levels 1 – 3 that are relevant for material processing. The third level represents a product and is linked to the BOM generated from SAP ECTR. From this link, SAP PPG then generates the complete project BOM.

A2 (TOS global): In this case, a PPG development structure that is neutral to customer orders is always created using the SAP ECTR-PPG integration. This structure, consisting of nodes and material variants, is called the node bill of materials. The order-neutral node BOMs can be reused for multiple sales orders. In the case of an order, the corresponding node BOMs are copied into the corresponding TOS structures. There, the structures are adapted to specific customer orders. Once the customer specifics have been completed, the project BOM is generated.

Wave 1

As part of the first introductory stage (Wave 1), approach A1 was implemented in the system. In the course of the Wave 1 project, the scope of requirements was expanded to include the creation of the Plant Maintenance objects required for service processes. For this purpose, equipment is created in TOS levels 1 & 2 functional locations and TOS levels 3 & 4, which correspond to the product and sub-product levels. The generated equipment is serialized with the material numbers used in the TOS. Thanks to the flexible concept and already existing standard functionality, this requirement could be added without changing the new processes that had already been defined.

"Thanks to the S/4 greenfield approach, document management could be completely rethought," summarizes Sebastian Fuchs, from BDF EXPERTS, looking back on the project: For this purpose, a Master Document Definition List (MDDL) was coordinated with all departments. The starting point was the content of the IEC61355 standard. This was narrowed down by your initial scope, which was necessary to meet the customer's requirements. The received list of documents was bundled into SAP document types and logically divided by a document structure using the SAP PPG in the TOS. As an initial document process, an exchange process was used to distribute documents from SAP by e-mail and to assign response documents to the previously outgoing documents.

"We Make Processes Work" – Lived Reality at QLAR

The TOS-light approach used provides the QLAR with the perfect basis for monitoring and controlling EtO processes. Furthermore, the TOS-light technology used is so flexible that it can be built on later when it comes to establishing further processes and implementing the topic of global TOS within the framework of Wave 2. SAP PPG also solves the challenge of filing at the document level and ensures that documents can be stored securely and used at all locations without redundancy. Mr. Martin Schütz, Sub-Project Manager EtO at QLAR adds: "We are looking forward to further cooperation and the deepening of the PLM strategy in order to continue to operate successfully for our customers on the market with the usual high quality and efficiency of QLAR. We Make Processes Work!"

Next Steps – Wave 2

In the second phase of the project (Wave 2), Schenk and BDF EXPERTS are implementing the Global Engineering Roll-out. The focus here is on the use of flexible node BOMs, the establishment of end-to-end document processes and automatic PS project generation.

More about Cideon

CIDEON advises and supports companies in optimising their product development processes – from conception and engineering to production and service.

As a system integrator and process consultant, CIDEON knows and understands the challenges companies face when it comes to digital transformation. With unique solutions, CIDEON ensures a continuous flow of data along the process chains, making data available throughout the company and economically usable. In this way, CIDEON customers can use the full potential of digitalization for themselves and their customers.

CIDEON uses state-of-the-art software solutions from the fields of CAD/CAM and PDM/PLM as well as software developed in-house. With more than 320 employees at 12 locations in Germany and Austria, CIDEON is part of the Friedhelm Loh Group. The family-owned company is successful worldwide with 12 production facilities and over 90 subsidiaries. The group of companies includes Rittal, Eplan, Stahlo and LKH.

Website: https://www.cideon.de/unternehmen/