18.04.2024

Configuration management for machine and plant operators

The last article discussed the benefits of configuration management for manufacturing companies in the transition from ETO to CTO (+). It explained the added value for the customer when the manufacturer uses configuration management.

But can it do more than just transmit information in a suitable form to the customer and thus to the operator of machines and systems? Can configuration management actively support the maintenance process?

Normative and legal considerations

Before we address this question, we should briefly look at the normative and legal situation to get a feel for the use of configuration management. In principle, many industries regulate the configuration management requirements of their respective suppliers via their quality management requirements. However, it is often not limited to the area of production and delivery but is continued as part of the maintenance of machines and systems at the operators. Examples of this are

- Defense sector: The NATO guidelines (e.g. AQAP-2110) not only contain the specifications for the suppliers of military equipment but also provide guidelines for configuration management on the operator side (i.e. the respective national armies such as the Bundeswehr).

- Aviation: The EASA (European Aviation Safety Agency) provides legal regulations for the European Union. The regulations (e.g. EASA Part 21) are intended to ensure the safety and airworthiness of aircraft. To this end, the regulations provide a framework for production and maintenance.

- Rail transport: The EU's 4th Railway Package, represented in Germany by the Federal Railway Authority, provides rail vehicle operators with clear rules for mapping the vehicle itself, as well as the roles involved in the maintenance process. This means that configuration management is not limited to the production of a machine or system, but considers its entire life cycle.

What is the difference in the use of configuration management between manufacturers and operators?

To do this, we need to look at the different objectives. Let's take the example of rail transport, specifically the manufacturer and the operator of a rail vehicle.

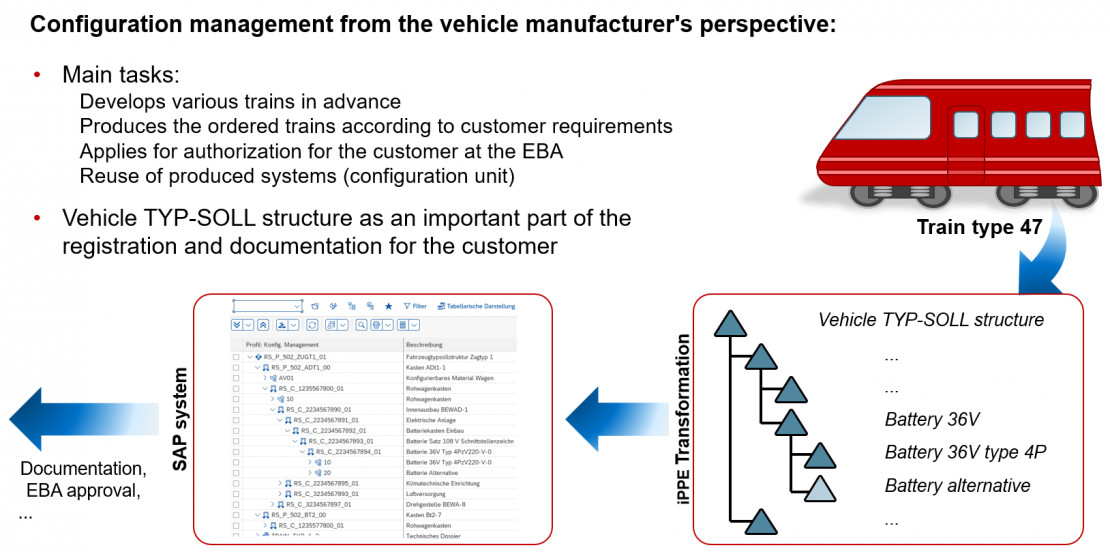

From the manufacturer's perspective, configuration management is used to map a target configuration for the delivery of a vehicle or vehicle type. In addition to mapping the configuration, configuration management also serves to create configuration units to significantly reduce development and production costs as well as throughput times in the long term through reuse (see also the previous article on the use of configuration management in the transition from ETO to CTO(+)) In rail transport, the vehicle is approved by the vehicle manufacturer, so the target configuration also serves to approve the vehicle.

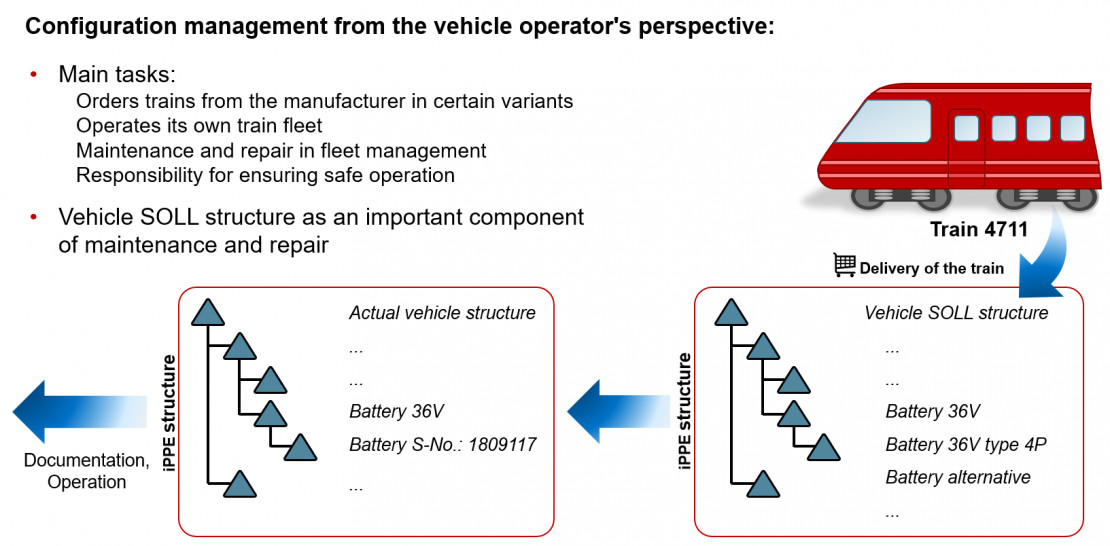

In contrast to the manufacturer's perspective, the reuse of configuration units does not play a role for vehicle operators. They do not want to develop new trains and therefore do not need to define reusable units in design and production processes. Instead, their objective is to check the data supplied by suppliers and transferred to the system, to identify identical parts across the entire vehicle fleet and to define a target configuration as a specification for the maintenance process. It must be possible to map changes transparently and implement them seamlessly throughout the entire process.

Which structures are necessary for mapping?

Three structures are necessary to map the operator's requirements in configuration management:

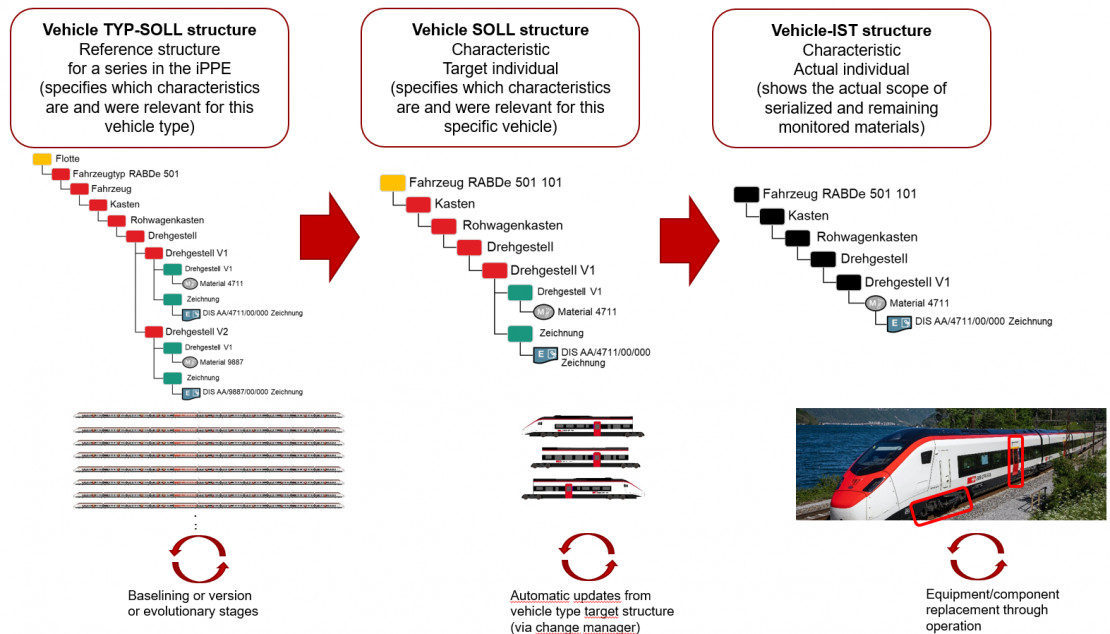

TYPE-TARGET structure: The TYPE-TARGET structure is the supplier's transfer structure. It contains the updates supplied by the supplier for a vehicle type until the final takeover (e.g. end of warranty). The TYPE-TARGET structure contains different variants of components and assemblies, which may also replace or exclude each other, as these are used on different vehicles of this vehicle type (different delivery statuses).

TARGET structure: A TARGET structure is required for each vehicle to be able to map the different delivery statuses. The target structure contains the permissible configuration for a specific vehicle. The target structure can contain alternatives to components or assemblies that are valid in parallel for this vehicle. As a rule, serialized components are not isolated in it, but are grouped in quantities like a parts list. The target structure usually contains a significantly larger number of components and assemblies than the actual structure.

ACTUAL structure: The ACTUAL structure contains those components and assemblies that are worth monitoring from a legal perspective or from the perspective of the vehicle operator. As a rule, these are serialized components and assemblies (e.g. wheelsets). Due to the effort involved in serialization, the ACTUAL structure does not contain the complete configuration of a vehicle.

What is a configuration check?

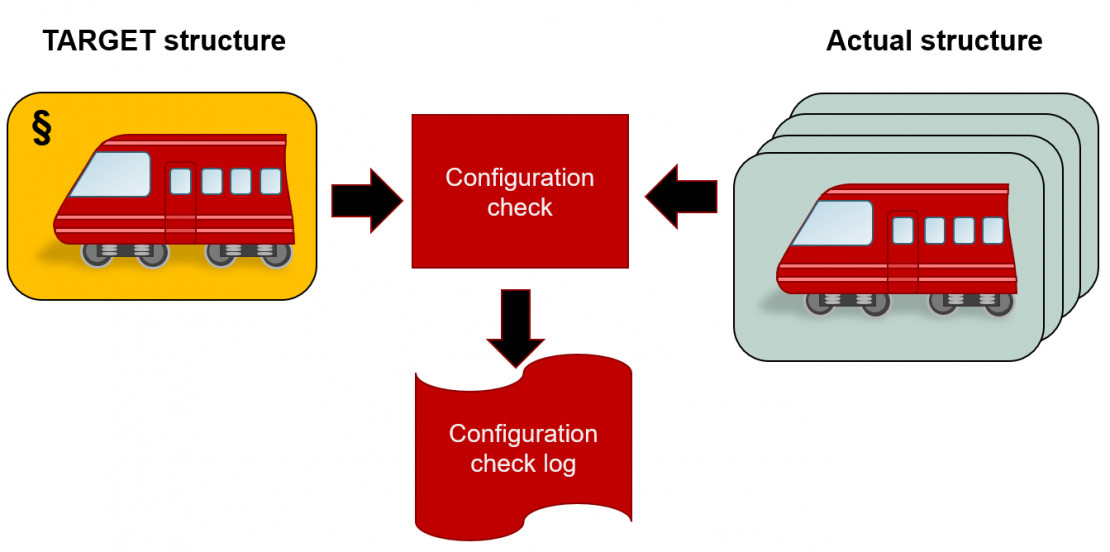

The configuration check enables the system to check whether the new part to be installed in this vehicle can be used in this position when removing a defective or worn part and installing its replacement. However, it is not only necessary to carry out a mundane check of the same removal and installation material. Instead, cases such as alternatives, predecessor successors or even dependent materials in the same or other assemblies (e.g. when replacing software) must also be taken into account. To make this possible, a configuration check is carried out using the TARGET structure of this specific vehicle when the ACTUAL structure (order for removal and installation) is changed. If, for example, an air conditioning unit is removed and a successor model is installed, this can have an impact on the necessary software version of the train, but also on temperature sensors installed at a different location. Therefore, the configuration check cannot be limited to one material but can relate to large parts of the target structure.

The result of the configuration check is displayed in a configuration check log. Depending on when the configuration check is carried out (ideally the first time the material is removed from storage for an order), the maintenance employee can see whether the material to be installed can be used and whether there are any dependencies on other components or assemblies.

The requirements for the configuration check are therefore high. Still, correct implementation also massively reduces component-related errors during maintenance measures and enables complete documentation concerning the target configuration of a vehicle.

Is configuration management only useful for highly regulated industries?

The examples of industries and the very specific example of the use of configuration management by operators relate to highly regulated industries. Here, configuration management and its use are already established and further developed (see updating the normative and legal basis such as the 4th Railway Package). The question now arises as to the extent to which its use also makes sense in less highly regulated sectors. Let's take a look at the standards. ISO 9001 and thus the ISO 10007 standard on configuration management, according to whose QM guidelines many companies are certified, presuppose the use of configuration management. However, configuration management also has general advantages for plant operators:

Safety and reliability: Well-managed configuration management enables the operator to ensure that all components and systems are configured according to the specified requirements and standards. This helps to ensure the safety and reliability of the systems or machines and reduce the risk of malfunctions or failures.

Efficient operations: By clearly documenting and tracking configuration changes, operators can achieve more efficient operations. They can ensure that all employees have access to up-to-date and accurate information about the equipment or machinery, resulting in improved work performance and faster responsiveness to changes or problems.

Cost efficiency: A well-executed configuration management minimizes the risk of errors or unexpected problems during operation. This can lead to less downtime, fewer repairs and lower operating costs. In addition, an optimized configuration can help to use resources more efficiently and avoid unnecessary expenditure.

Compliance and certification: In many industries, especially in regulated sectors such as aviation, healthcare or defence, operators are required by law to comply with certain standards and regulations. Effective configuration management supports the operator in meeting these requirements and facilitates the certification and compliance process. Long-term maintainability and development: By systematically managing configuration data, operators can improve the long-term maintainability and development of their systems or machines. They can plan, implement and track changes to optimize performance and functionality over time and extend the life of the equipment.

Now back to our initial questions

Can configuration management do more than just transmit information in a suitable form to the customer and thus to the operator of machines and systems? And is the use of configuration management able to actively support the maintenance process?

Both questions can be answered with a clear "yes" after the above explanations. Effective configuration management offers operators the opportunity to operate their systems or machines more safely, efficiently and cost-effectively while ensuring compliance with standards and regulations.