19.01.2024

Configuration management as a path from ETO to CTO(+)

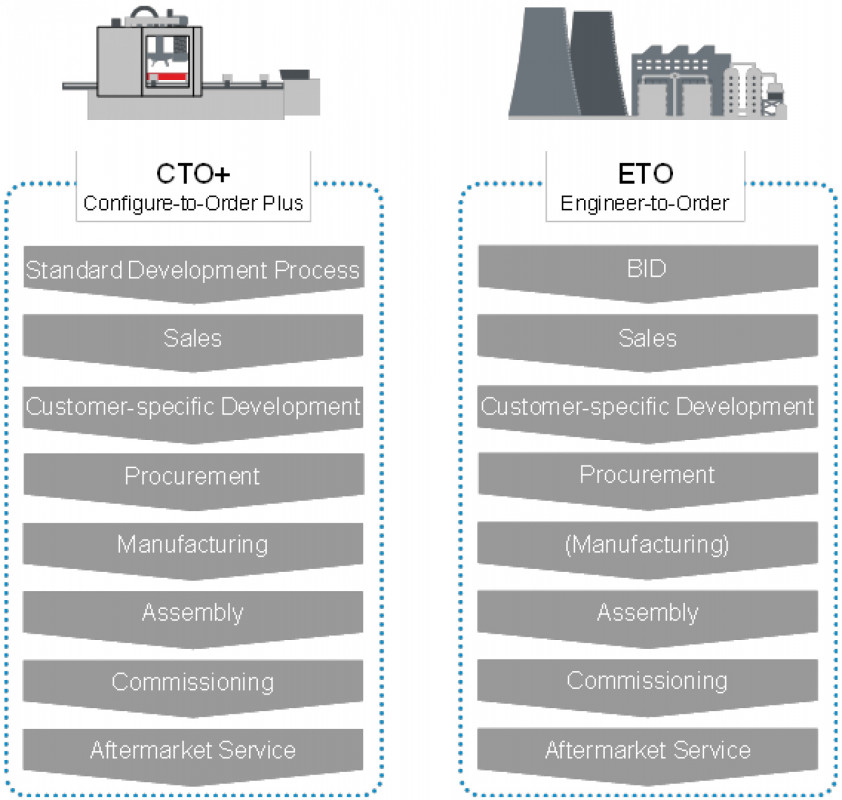

The transformation from ETO (Engineer-to-Order) to CTO (Configure-to-Order) or CTO+ (Configure-to-Order with Engineer-to-Order shares) is considered by many companies to be the way forward.

ETO and CTO+ – a brief description

ETO (Engineer-to-Order) is a production approach that is characterized by the fact that the design does not begin until the order has been placed. As a result, the order-specific requirements are not fully known at the time of placing the order, but there is a rough arrangement in the bid phase. This means that a large part of the design work has to be carried out after the order has been placed. The ETO approach is characterized by a high degree of individualization of the product for the customer.

CTO+ (Configure-to-Order Plus) is a production approach that is characterized by configuring a standardized, multi-variant product for an order to meet the customer's requirements. The design work for the standard product is carried out before the order is placed. In the CTO, individualization is limited to the variants of the product. The plus share ("+") in the CTO+, in turn, describes the ETO share in a CTO order (e.g. material loading or basement).

Why is that?

ETO entails many risks for the company:

- High concept risk: Due to the high complexity of many products, conceptual errors can occur during design that are only discovered very late (too late).

- High customer influence: Due to the total degree of individualization, the customer often not only dictates the characteristics of the product, but also specifies conditions for the development process and project management. The company must be able to re-adapt to these conditions for each customer in order to receive orders.

- High internal costs: High personnel costs, especially in design, documentation and project management, increase overall costs and squeeze margins. These costs are incurred as one-off costs.

- Competitive prices: the high internal costs lead to high selling prices for the products. These prices must also be able to be paid by the customers.

On the other hand, there is the possibility of total individualization of the product for the customer in the ETO.

CTO(+) offers the customer only a part of customization. There can be an apparent individualization via the configuration (CTO) and a real individualization (+). However, real individualization is limited in order to be able to successfully carry out CTO+:

- Individualization may only make up a small part of the overall product.

- Individualization may only occur at certain points of the product (e.g. material loading).

- Individualization may only take place according to specified conditions.

If we now transfer the risks from ETO to CTO, we come to the following conclusion:

- High concept risk in the ETO: The use of standard building blocks significantly reduces the concept risk in the CTO. Individualization is limited and thus also limits their concept risk.

- High customer influence in the ETO: The influence of the customer, especially on the development process, documentation and project management, is pushed back in the CTO. Standard modules are used with existing documentation and procedures.

- High internal costs in the ETO: By using standard building blocks, the costs are spread over several orders, which reduces the average costs in the CTO. Due to the lower customer influence, costs in development, documentation and project management are also saved through standardized processes.

- Competitive pricing in the ETO: The total cost of the product drops significantly in the CTO. The price becomes more attractive for the customer despite the lower level of customization.

This means that the customer has fewer options for customizing the product, but receives a lower price and a lower concept risk.

This is all quite abstract. An example from an area that is familiar, at least in part, simplifies the understanding of the process: suits.

A quick Google search for the cost of different types of suit manufacturing yields the following result:

- An off-the-rack suit ranks at around 500 euros (MTS) in the upper price segment.

- A made-to-measure suit costs around 1,000 euros (CTO).

- A custom-made suit, on the other hand, costs between 3,000 and 6,000 euros, depending on the material and design (ETO).

From this simple, reduced example, we can already see the costs of individuality and the benefits of standardization.

How is it possible to move from an ETO-driven organization to a CTO-driven organization?

That's where configuration management comes in. Configuration management, according to Marcus Grande's "100 minutes for configuration management", is a management discipline aimed at establishing and maintaining consistency between product performance and the functional and physical properties of the product.

Configuration management has the following tasks:

- Definition: Specification of the frame conditions for the documentation of the configuration (configuration management planning)

- Integrity: Ensuring the integrity of the product by means of target definition and actual monitoring (configuration identification, configuration audit)

- Reproducibility: Reproducibility of previous configuration statuses (configuration accounting)

- Transparency: Display of distinctions between configurations at different points in time (change transparency, change control)

Typically, configuration management defines configuration units (or artifacts) in the product. A configuration unit can be the entire product, but also a single component or everything in between. The configuration unit maps a product in its entirety. This means that it is not limited to the pure material view (comparable to a material master in SAP), but contains its documentation, historical statuses (baselines), changes that have been made and are currently being made, as well as uses in orders, and information about the physical representative (e.g. SAP equipment).

By means of the configuration unit, the Form-Fit-Function corridor can be mapped transparently. The Form-Fit-Function Corridor, the term coined by Prof. Dr. Jörg W. Fischer of the Steinbeis Transfer Center for Computer Use in Mechanical Engineering (Form Fit Fuction Corridor - Jörg what do you do), describes the revision possibilities of the configuration unit from the perspectives of the stakeholders involved.

FFF is often defined from a design point of view, which leads to problems, especially in service. An example of this: A purchased part with defined connections can still be FFF from the point of view of the design if its components change but the connections, function and design do not change in the process. From the service point of view, however, this may very well be an FFF deviation, as other spare parts are now relevant for this purchased part. A precise definition and monitoring of compliance with the revision process of a component or assembly without active intervention in it is very helpful here by an overarching authority (Configuration Management Unit).

In ETO, the part is often defined and used only once for an order, in the CTO the part is reused in different orders, so the view of the entire FFF corridor is essential here. An overarching instance that is responsible for a configuration unit promotes correct classification in the FFF corridor over the entire life cycle.

Where can configuration management help?

By defining, creating, maintaining and documenting the configuration unit, ETO components, assemblies and products can be translated into units that can be used in the CTO for configuration. The configuration units previously created in ETO can be combined into a new product within the CTO process and supplemented with ETO components (which in turn can also become CTO-capable units). Configuration management not only focuses on the design view of FFF, but also on the entire life cycle of the configuration unit. In this way, configuration management accompanies the transfer of ETO-related units to CTO-capable units, promotes the stability of the units relevant to the CTO and ensures their correct revision.

Configuration management can therefore actively support the step from ETO to CTO.

Do the benefits only lie with the company or does the customer also benefit?

At first, you might think that by moving from ETO to CTO+, the customer loses. After all, he has to give up the possibility of total individualization. That this is not the case, we have already briefly described above. However, configuration management also has additional advantages here. Its task is to monitor the documentation of the product. Especially for companies with high complexity, high conceptual risk and serious consequences in the case of failure or in the case of an error, complete documentation is essential and therefore configuration management is already standard or even legally binding in these industries (e.g. railways, military, aviation). As a result, the documentation of the standardized configuration units is usually much more professional and much more comprehensive than in comparable ETO projects. This means that the customer receives complete, correct documentation that is suitable for his product. The usual ping-pong regarding documentation documents and versions between companies and customers is no longer necessary.

In addition to the documentation, he receives a standardized process for changes that is based on the configuration units that are relevant to him. Changes during project management (e.g. due to necessary revisions to standard products) or during the warranty and operating phase (e.g. due to obsolescences) can be handed over by the company to the relevant customers with all relevant information (e.g. replacing configuration units). This means that the customer feels that the company is providing them with all-round competent support and is fully informed. This also has a positive effect on the company's public image.

So configuration management not only benefits the company, but also the customer.