06.09.2022

Comprehensive Configuration Management

|

Customer |

thyssenkrupp Marine Systems GmbH |

| Industry |

Naval shipbuilding and electronics |

| Products and Services |

System provider for submarines and naval vessels |

| Locations |

Bremen, Emden, Flintbek, Hamburg, Kiel, Wedel, Wismar |

| Size |

6000 employees |

|

Website |

The project in brief:

| Challenge:

|

The introduction of configuration management with the interaction of different systems |

|

Task and objective: |

Introduction of configuration management using SAP PPG |

| BDF products and SAP modules used: |

SAP iPPE, SAP PPG |

|

Customer benefits: |

Complete configuration structure for the product in the SAP system |

Thyssenkrupp Marine Systems GmbH is the leading European system provider for submarines and naval vessels. As a technology and service leader in the European naval industry, thyssenkrupp Marine Systems is consistently driving the “digital yard” goal. To master the complexity of product development in technologically demanding and long-running projects, a comprehensive configuration management is sought.

Configuration management throughout the product lifecycle

As defined, “configuration management is a management process to make and comply with product deliverables, as well as functional and physical properties of the product throughout the product lifecycle” (freely translated according to ANSI/EIA-649-A).

The goals of configuration management are:

- Ensuring the integrity of the product

- Reproduce previous configurations at any time

- Make content and differences of different configurations visible at any time

- Traceable and traceable changes

- Adherence to planned costs and framework

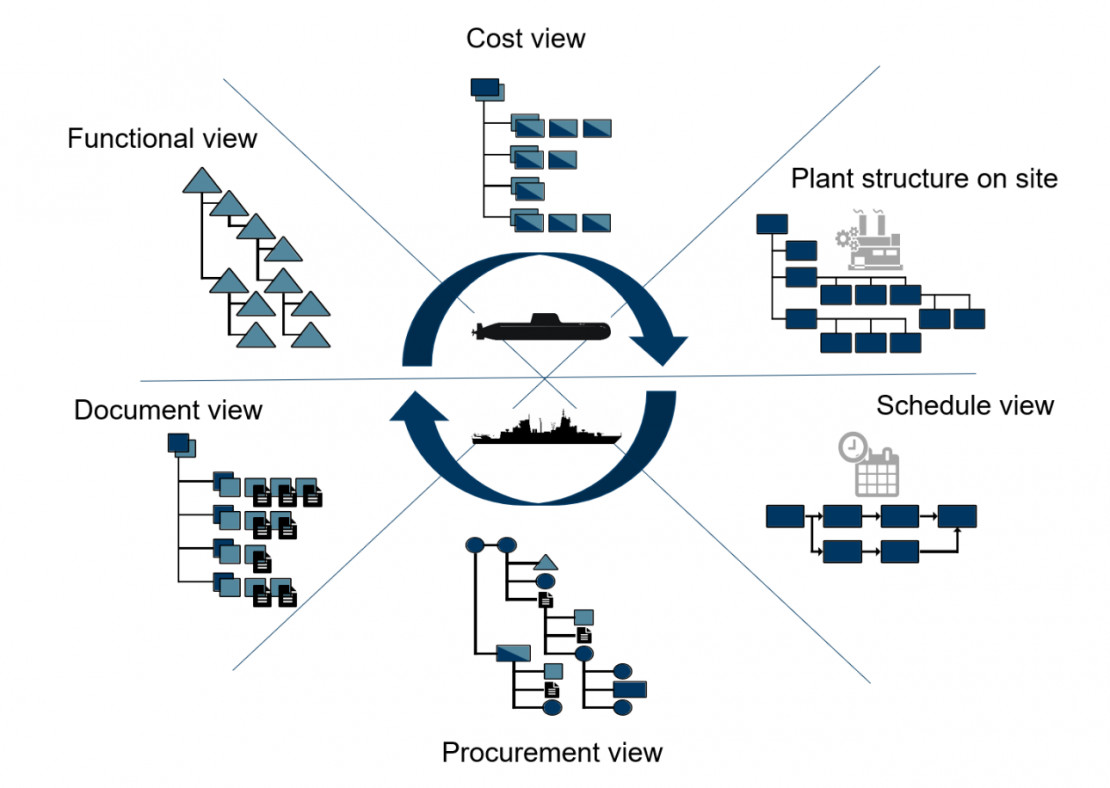

The information distributed in the system landscape (SAP ECC, authoring systems, requirements systems) is to be combined in a configuration structure using a middleware in the SAP system to fulfill the targets.

SAP Product and Process Governance by BDF - The Core of the Configuration Structure

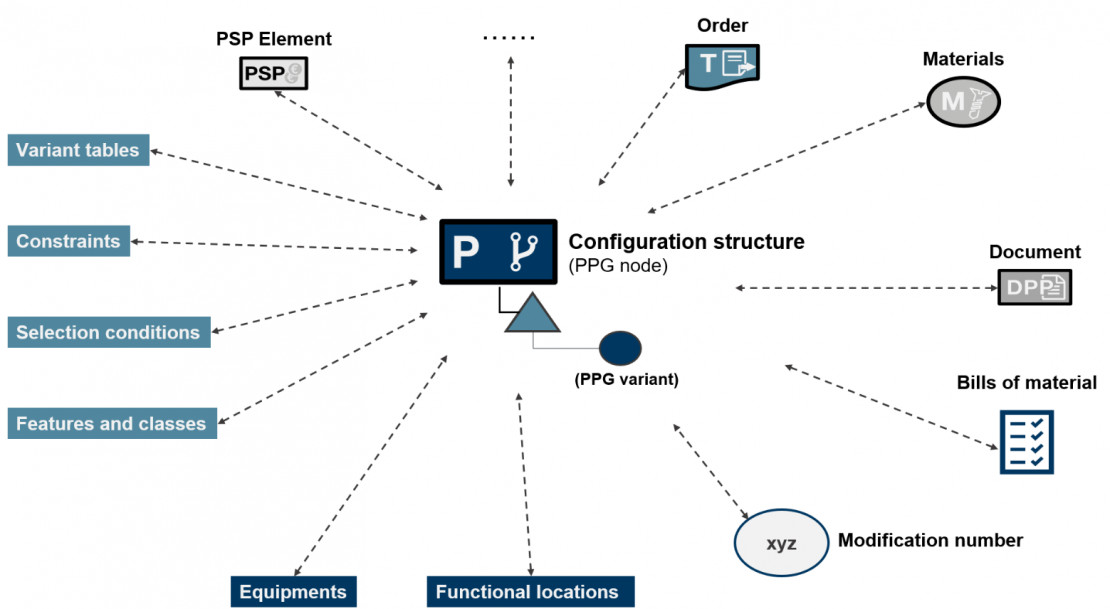

SAP Product and Process Governance by BDF (SAP PPG) and its configuration structures are used to map configuration management. The PPG node with its PPG variants forms the nucleus of the configuration structure and offers the option of combining various SAP objects, information, and processes.

Active Planning of Process or Objects

| Planning Objects | Planning Processes |

|

|

Depending on Customizing, the PPG node can be used for different tasks within a structure by assigning different tab pages (views), links, and functions to it.

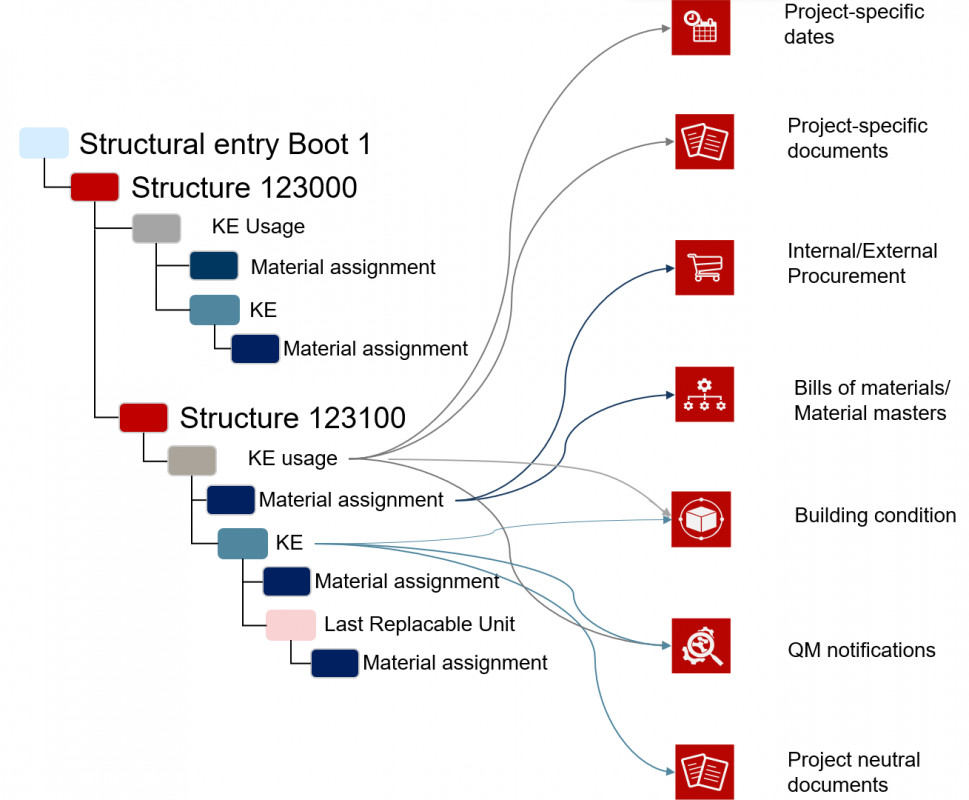

The PPG node is also used as a configuration unit (“KE”) in the context of configuration management. The PPG node with a material master assigned via a PPG variant (1-n) as well as assigned document info records and metadata forms a configuration unit. Depending on the general and item related status, this configuration unit can be used in a structure or can also be restored. In addition to the project-neutral configuration unit, a project-specific configuration unit ("KE usage") is also used in the configuration structure to map project-specific information. For example, the CU usage is used to assign only the material master used at this point.

The configuration unit and the configuration unit “CU Usage” are largely defined by engineering. The Last Replacable Unit (last component that can be exchanged individually) is used to map the further detailing of the individual materials created by the service. This can further detail the configuration unit (project-neutral) or the configuration unit usage (project-specific) at any depth. The configuration structure for a product is built from these modules and other outline levels. The structure and materials used come directly into the configuration structure via integration with a middleware from the authoring and requirements system.

Alternatively, the entire structure or parts of it (for example a structure or the Last Replacable Units) can be imported directly into the system via a load file and new structures can be created or existing structures changed. For the migration of existing products in particular, this is a suitable way of bringing existing products to the current stage of the process.

At various levels within the structure, various information is available and objects are linked, giving an overall picture of the configuration beyond the engineering view. Direct integration with logistics (purchasing and production), as well as internal quality management and the construction condition (mapping of functional locations and equipment) complete this screen.

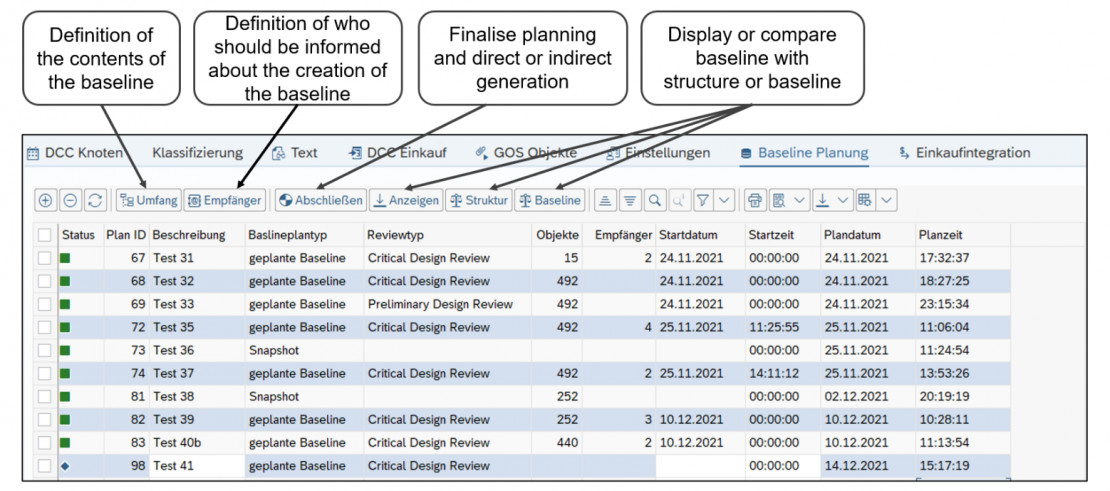

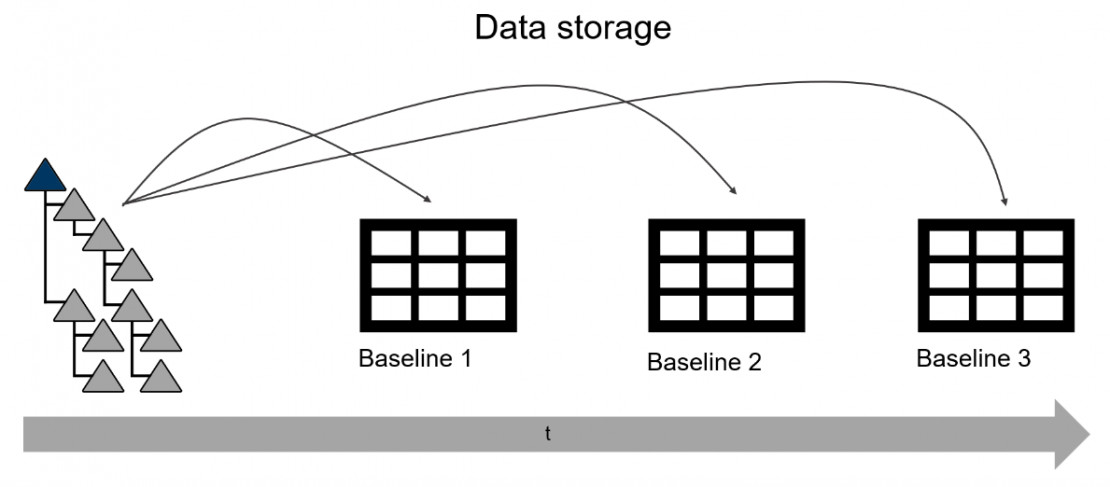

Based on this structure, baselines (which describes, among other things, a series of released documents with specific revision levels that fully define a configuration at a certain point in time) can be planned to represent the individual milestones within the product lifecycle, define their scope, define recipients, and generate them automatically.

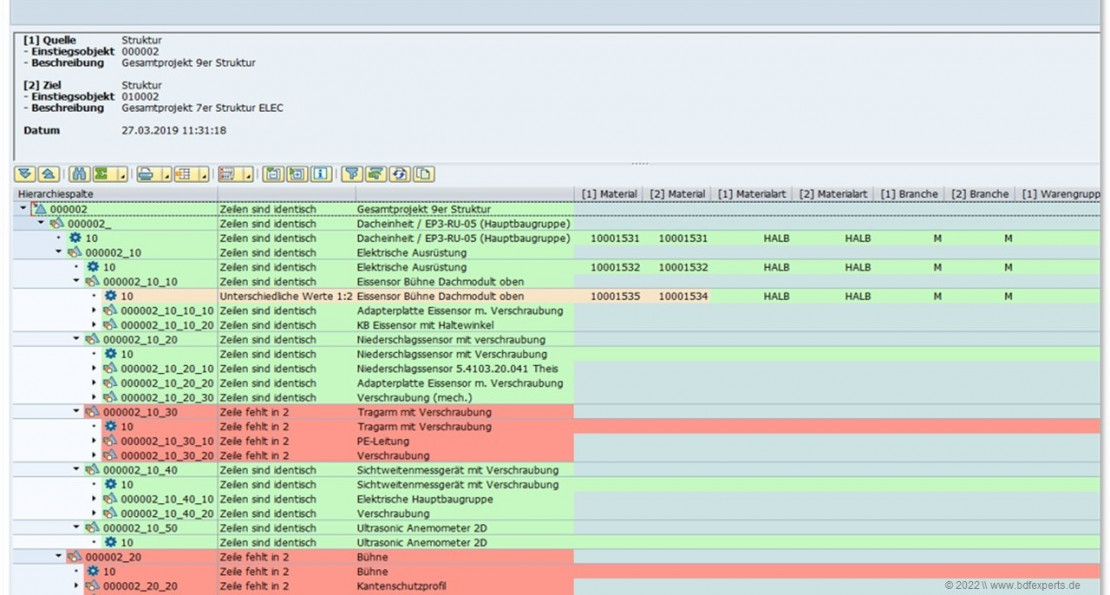

The baseline is created as a representation of the structure and can be compared with other baselines or the structure. Differences are displayed and can be traced in the individual comparison.

All information about the configuration of the product in one central location

The configuration structure enables the configuration manager to have a sufficient view of the status of the product. Due to the integration with the authoring and requirements systems, the current data from the system landscape is always available in one place. As a result, the information procurement effort has been reduced. In addition to mapping the target configuration, the structure can also be used to plan and track the planning status using Progress Tracking (for example, “As Sold” comparison with current target structure status). The structure information can also be used as a product structure for integration into logistical processing. By merging the data, extensive baselines of the product can also be created and used for internal development progress and communication with external partners. From a change management perspective, dependencies to changes can be easily identified and their impact can be determined. Changes can then also be forwarded to the respective objects and their confirmation processed. Finally, by applying the functional location and equipment structure associated with the configuration structure, the manufactured product is also represented in the serialized construction condition.