30.10.2025

Guest article: A new solution for engineer-to-order manufacturing

Guest article by Thomas Haemmerle, Senior Manager - SAP - Advisory at KPMG

The challenge

SAP S/4HANA as an ERP system has already proven its strengths in production planning and execution for make-to-order (MTO) processes many times over, as it enables instant integration between sales, production planning and materials management. But what happens when the production part requires extensive design and engineering activities and collaboration due to the complexity and specificity of customer requirements?

How can this be managed in an integrated way in S/4HANA, especially in complex industries such as manufacturers of electronic components for the semiconductor industry, equipment for the chemical and oil and gas industries, national rail infrastructure or extensive cooling/heating systems?

In all of these industries, KPMG has used its KPMG Powered methodology to accelerate the vision, validation (design) and construction phases of S/4HANA transformations, and has either implemented or positioned SAP's "secret weapon" for managing design and engineering challenges in Engineer-to-Order (ETO) and Configure-to-Order (CTO) environments: Product & Process Governance by BDF (PPG).

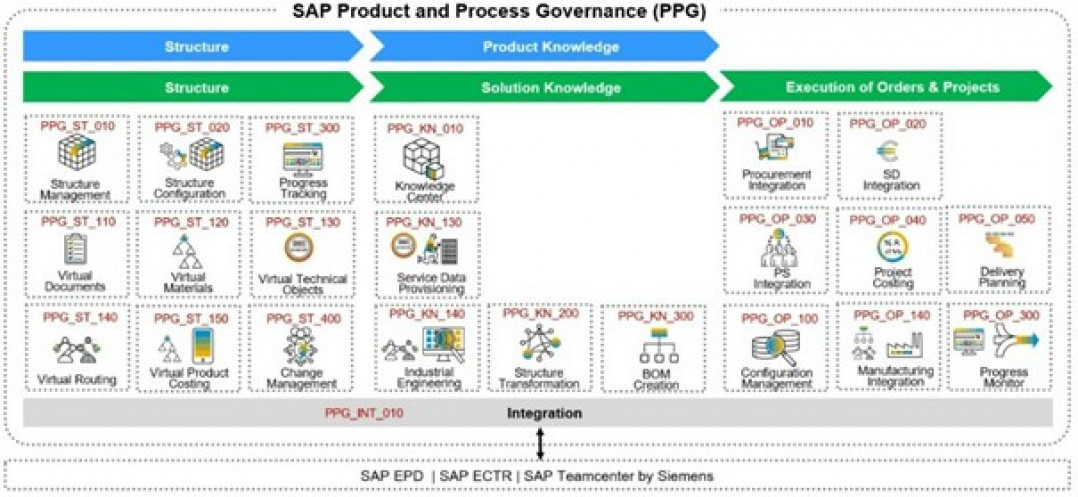

PPG solution components Highlights

Structure Management & Configuration

Module libraries support the efficient development and management of order-neutral or order-related product structures. The product structures can be built without SAP material numbers using different structuring approaches, such as functional, modular, logistical, etc. Different configuration cases can be mapped in the PPG structure, and rule-based configuration can be carried out at all levels of the structure, from top to bottom or bottom to top, with structure configuration in TOS supporting the cases of CTO, CTO+ and ETO.

Progress tracking

Progress tracking is available at the lowest level for detailed planning in every project phase. Based on the overall schedule with milestone dates, the production and procurement processes are planned with PSP elements and network plan operations.

Virtual materials and technical objects

Virtual materials enable the holistic planning of product structures, if necessary also in modular form. The creation, configuration and generation rules for the required environment objects of a material master in SAP are stored in these structures.

Virtual technical objects support the planning and subsequent automated generation of data for plant operation and operational lifecycle management. The development of a digital twin for subsequent plant operation consists of several essential components for operational service, customer documentation and spare parts lists, using virtual technical locations and virtual devices.

Data from non-SAP systems can be transferred via interfaces to CAx, PDM and PLM systems.

Virtual product costing

Costing in the early development phase of a product, production plant or an entire plant, based on the product structure, supports costing before material masters and material BOMs have been created in SAP and can be determined using a standard SAP product costing with or without quantity structure.

Knowledge management

The modeling of product and configuration knowledge is supported by the Knowledge Center in PPG. The results can be used directly in the SAP variant configuration or made available to external configurators. With characteristic rooms, the same characteristics can be used in different contexts, which significantly reduces the number of characteristics required.

Provision of service data

The planning data from PPG can be used to build a digital twin for the subsequent operation of the plant and is supplemented with data from operational ERP processes. Based on the technical structure and its functional elements, the technical location structure and the associated equipment can be generated for an entire plant complex.

Integration with projects, manufacturing, procurement, sales and logistics

PPG is closely integrated with the other S/4HANA modules that support the development, engineering and prototyping processes: project systems (PS), production planning (PP), procurement (MM), sales and distribution (SD) and logistics (LE).

PS integration is at the center of an ETO process, an order-oriented design or complex development projects. The PPG TOS (Technical Order Structure) globally defines the scope of supply and services to be provided (documents, material, services). These contents can then be processed across projects in the respective delivery organizations. The integration of the TOS items into PSP element and network structures is rule-based and automated.

Integration with external systems (CAD, PLM)

PPG supports various methods for connecting external systems. Communication with PLM systems is enabled via the SAP PLM interface or PPG services (APIs, WebServices, XML), and the integration of the SAP Engineering Control Center (ECTR) with PPG can be used for the direct integration of CAx systems. In the case of synchronous integration, the systems communicate in real time and with direct feedback via PPG APIs, which are called up from the source system. In the case of asynchronous integration, XML files from external systems are read and interpreted by PPG.

BDF and KPMG - perfect interaction

We are pleased to partner with KPMG to offer the SAP Product & Process Governance (PPG) solution that efficiently integrates engineer-to-order processes. By working closely with KPMG, we can help customers optimize their design and engineering processes and strengthen collaboration across multiple systems. We help companies master their unique processes and gain end-to-end control over the entire lifecycle of their projects. Contact us to learn more about PPG's capabilities and how it can transform your business processes.

SAP Product and Process Governance

Produce and offer highly customized products cost-efficiently with SAP PPG.