28.04.2025

Groz-Beckert introduces SAP PPG in product development

The project in brief:

Challenge:

Creation of an integrated approach, with a PLM system within the ERP environment with end-to-end integration.

Task and objective:

Replacement of a legacy PLM system with the creation of a central product database in SAP ERP.

BDF products and SAP modules used:

SAP PPG, SAP iPPE for product data structuring with integration of production-relevant information and provision of SAP PP master data such as the material bill of materials.

Customer benefits:

Centralized product data management in SAP ERP with a high level of integration for providing information within production using SAP FIORI-based APPs.

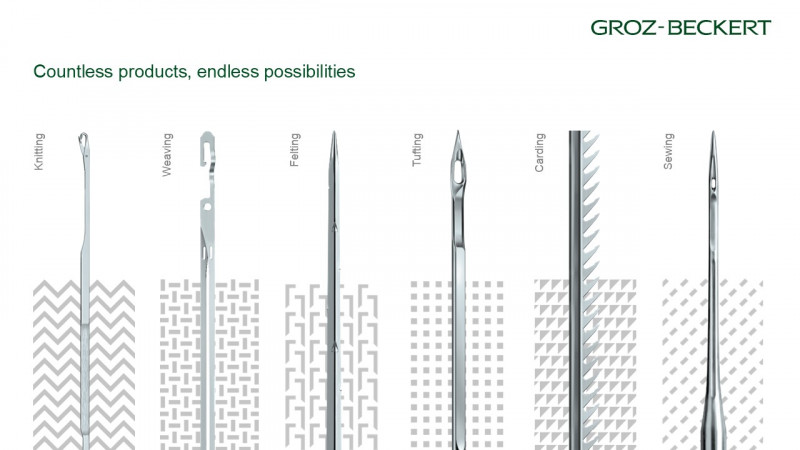

Groz-Beckert KG is the world's leading supplier of industrial machine needles, precision parts and fine tools, as well as systems and services for the production and joining of textile surfaces.

Groz-Beckert offers 50,000 products in the knitting and warp knitting segment alone:

A large number of tools are required to manufacture a needle, which are structured in different production steps. Maximum precision in the storage of the corresponding product and production data for the needles is essential. The design of the products begins in the Siemens NX CAD system. In the past, the product information was instantiated and enriched with additional parameters in a PDM system located outside of SAP ERP. Groz-Beckert turned to BDF EXPERTS to create an integrated PLM system with a central product database within the ERP environment. In 2009, Groz-Beckert introduced the SAP Engineering Control Center (SAP ECTR) in collaboration with our partner DSC Software AG. Since 2023, more and more products have been added segment by segment to the PLM near ERP with the help of SAP PPG Product and Process Governance (SAP PPG). This approach is also used outside the Albstadt site, within the entire Groz-Beckert Group.

Different product segments & product types, one PLM in ERP

Groz-Beckert offers a wide range of products and services for the textile industry. The main product segments include knitting, weaving, nonwovens, tufting, spinning and sewing. In the knitting segment, the range includes needles and system parts for various knitting technologies. In weaving, Groz-Beckert offers products for weaving preparation and weaving itself. To produce nonwovens, the company provides products and services for needling and bonding. In the tufting segment, solutions are offered for carpet production. The product range also includes components for the spinning process as well as sewing machine needles and accessories for industrial sewing applications.

SAP PPG makes it possible to display product structures based on SAP iPPE within SAP ERP. The respective products types are mapped in content structures. An associated master structure for each product group gives the designer/modeler an overview of the basic valid production steps and can thus equip the product, or the exact typification of the product, with the correct steps. By filling the content structures, database relationships are created to the master structure, which offer the possibility of making mass changes in a centralized manner.

Within SAP PPG, initial distinctions can be used to make, view or change the content of authorization delimitations. The flexibility of SAP PPG also allows products to be mapped manually in new content structures without prior CAD integration. The solution thus supports the complete mapping of all product data of the various products and also forms the bridge to production, as explained in more detail below.

Standardized product structures and multi-level parts lists

Due to the generic and structural setup in SAP PPG, based on SAP iPPE, it was possible to adopt similar structures from the old PDM system. However, process-related adjustments led to optimization of the structures and the development of future, more efficient structural principles.

A holistic structural concept was created with the procedural and technical support of BDF EXPERTS. This concept includes so-called master and content structures in order to have a complete overview of available production steps, which are then merged with the components of the respective product to be mapped. Smart drag-drop options also offer a simple user experience.

Specifically, however, we are not yet talking about an SAP ERP bill of materials, but about SAP iPPE structures. iPPE structures make it possible to build the potential bill of materials in a more flexible and user-friendly environment and to use this structure as a derivation basis for bills of materials at the end of the process chain.

Building on the product data model based on SAP Product and Process Governance (SAP PPG by BDF), Groz-Beckert also developed an SAP FIORI app for displaying models and corresponding production data relevant to the respective plant. An integrated approach was thus implemented, which is based on the fact that data is managed at a central location but can be used in different areas of the process chains within production.

ONE central system for all products

SAP Product and Process Governance (SAP PPG by BDF) thus represents the foundation on which stable and future-oriented environmental processes can be built. The strong SAP PPG data model also helps to adapt to changing conditions during needle takeovers, for example, if various structuring objects can no longer be identified from the old system due to the age of the needle.

More about Groz-Beckert KG

Location: Albstadt (17 worldwide)

Industry: Textiele precision tools

Products and services: Industrial machine needles, precision parts and precision tools, matching systems and services

Over 70,000 products in total

Number of employees: 2,219 in Albstadt (approx. 9,500 worldwide)

Groz-Beckert is the world's leading supplier of industrial machine needles, precision parts and fine tools, as well as systems and services for the production and joining of textile surfaces. Headquartered in Albstadt, Germany, the group of companies is represented in over 150 countries with more than 9,500 employees. It combines more than 120,000 products in the areas of development, production and sales of process-critical textile precision tools, industrial cutting solutions and solution providers for textile construction and high-performance fibers.

Website: https://www.groz-beckert.com/

More about BDF EXPERTS

BDF provides the EXPERTS in SAP consulting and software development in the areas of:

- Product Lifecycle Management

- Supply Chain Management

- Service and Asset Management

- Corporate Finance & Treasury Management

based on S/4 HANA and SAP ERP.

We advise large SMEs to global corporations in the DACH region. As a team of digitalization experts, we digitalize and optimize our customers' data and processes. With our product, SAP PPG Product and Process Governance, we support digital business processes from product creation to product service. With the BDF Cash Position Cockpit (BDF CPC), we optimize the financial supply chain. Together, we get the most out of your SAP world.

Website: https://bdfexperts.de/en#home